ERC Project

Liquid bridges for solid matter

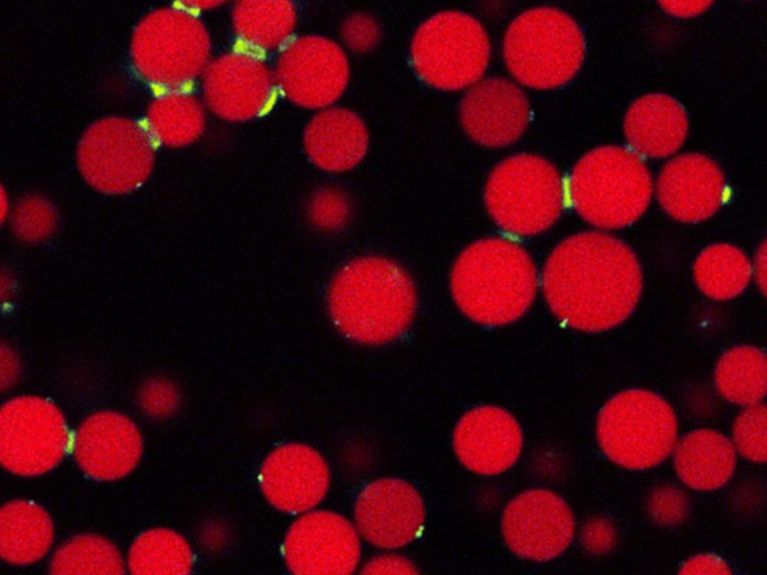

Photo: Erin Koos

Erin Koos has developed a new method that can improve material properties. This could be used for the production of customized products such as plastics made ??with little softening agents. Since August 2013, the European Research Council (ERC) supports her work at the Karlsruhe Institute of Technology on so-called capillary suspensions with the ERC Starting Grant.

Suspensions are mixtures with a viscous to gel-like consistency, comprised of a liquid in which solid particles are evenly distributed, such as paint and molten chocolate. The method developed by Koos consists of adding a second, immiscible liquid to the mixture. This liquid forms bridges between the solid particles, resulting in a stable meshed structure. The advantages of this procedure over conventional suspensions go beyond stability, however. “The new method makes it possible to fine-tune the desired material properties in advance by combining different liquids,” says Koos. The method could be used to manufacture ultra-lightweight and resilient building materials, but also, for instance, filters made from glass which are both porous and robust.

Erin Koos leitet die Gruppe Kapillarsuspensionen (CapS) am Karslruher Institut für Technologie. Foto: KIT

The 33-year-old’s arrival at the KIT was anything but a coincidence, however. Koos had set herself a clear objective: “I wanted to take the next step on the road to becoming a professor and conduct independent research with a group of my own. I also wanted to experience a different academic culture.” She found both things at the KIT: a research topic that interested her, and colleagues willing to support her in developing her career. “The KIT helped me find the right funding opportunity with the ERC grant.”

Her group, comprising two PhD students and a post-doc, is still coming together. She has already been able to buy a laser microscope that generates three-dimensional images. “We use it to examine the physical processes caused by capillary action on a scale of a few micrometres,” says Koos. The nature of the capillary bridges enables the researcher to determine the force exerted between the solid particles. “And if we can describe the microstructure, it helps us predict how the material will behave in larger amounts.”

By the end of the five-year funding period, Koos hopes to understand the underlying principles and effects of capillary action in suspensions. But that is not all: “It would be nice to develop some prototypes in collaboration with industry. Then I could say: my ideas contributed to the design of this product.”

Grant:Starting Grant-2013

Research field:Process Engineering, Material Science

Panel: PE2

Principal investigator:Dr Erin Koos

Host institution: Karlsruhe Institute of Technology

Funding period:1 Aug. 2013–31 July 2018

ERC funding:€1,489,618

Readers comments