|

||||||||

|

||||||||||||||||||||||||

|

|

At Helmholtz, September was all about the annual conference in Berlin: The summer gave us one last hurrah, with an entertaining evening at the Radialsystem on the Spree, where the topic was health research. Our point of view ties in with this: Scientific Director of the Max Delbrück Center, Maike Sander, believes that the Helmholtz association is well positioned in biomedical engineering and that in order to advance the topic, all the pieces of the puzzle must now be cleverly assambled and people from different research areas brought together. In our interview, you can find out what neuroscientist Sabine Krabbe from the German Center for Neurodegenerative Diseases (DZNE) finds most exciting about her job. And the Helmholtz-Zentrum Dresden-Rossendorf is using a special small laser at the European XFEL to compete with the most powerful lasers in the world. Enjoy your reading! |

|

|

|

|||||||||||||||||||||||

|

|

|

|||||||||||||||||||||||

|

|

|

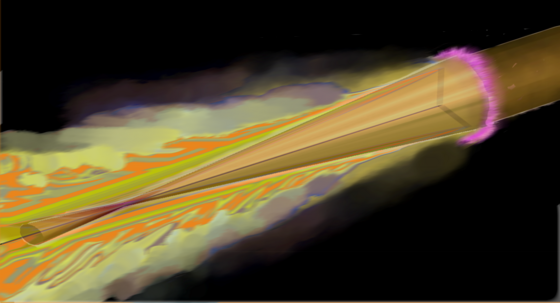

Extreme conditions prevail inside stars and planets. The pressure reaches millions of bars, and it can be several million degrees hot. Sophisticated methods make it possible to create such states of matter in the laboratory, albeit only for the blink of an eye and in a tiny volume. So far, this has required the world's most powerful lasers, such as the National Ignition Facility (NIF) in California. But there are only a few of these light giants, and the opportunities for experiments are correspondingly rare. Scientists from HZDR and European XFEL, have now succeeded in creating and observing extreme conditions with a much smaller laser. At the Eurpoean XFEL, the HZDR operates via the international user consortium HIBEF – Helmholtz International Beamline for Extreme Fields a laser, which generates ultra-short pulses that do not have particularly high energy, only about one joule. However, at 30 femtoseconds, they are so short that they achieve an output of 100 terawatts. The research team used this laser at HED-HIBEF to fire at a thin copper wire, just 25 micrometers thick. “Then we were able to use the strong X-ray flashes from the European XFEL to observe what was happening inside the wire,” explains Alejandro Laso Garcia, lead author of the paper. “This combination of short-pulse laser and X-ray laser is unique in the world. It was only thanks to the high quality and sensitivity of the X-ray beam that we were able to observe an unexpected effect.” The measurements showed that the density of the copper in the middle of the wire was briefly eight to nine times higher than in “normal”, cold copper. “Our computer simulations suggest that we have reached a pressure of 800 megabars,” says Thomas Cowan, director of the HZDR Institute of Radiation Physics and initiator of the HIBEF consortium. “That corresponds to 800 million times atmospheric pressure and 200 times the pressure that prevails inside the earth.” The temperature reached was also enormous by terrestrial standards: 100,000 degrees Celsius. These are the conditions that are close to those in the corona of a white dwarf star. “Our method could also be used to achieve conditions like those in the interior of huge gas planets,” emphasizes Laso Garcia. The new measurement method should not only be useful for astrophysics, but also for another field of research. “Our experiment shows in an impressive way how we can generate very high densities and temperatures in a wide variety of materials,” says Ulf Zastrau, who heads the HED group at the European XFEL. “This will be an important step further for fusion research.” Several research teams and start-ups around the world are currently working on a fusion power plant based on high-performance lasers. Publication: Cylindrical compression of thin wires by irradiation with a Joule-class short pulse laser, in Nature Communications, 2024 (DOI: 10.1038/s41467-024-52232-6) Picture:HZDR / T. Toncian Also: Giant black hole plasma jets surprise experts |

|

The most exciting thing is always having the opportunity to discover something new that no one has ever seen before. Unfortunately, as a group leader, I’m not in the lab as much anymore and I rarely get to experience this myself during an experiment. However, it is now particularly rewarding to watch the development of young researchers. From the initial cautious pride just because something worked, the enthusiasm grows with more and more expertise, until at some point they have the knowledge and confidence to assess the significance of their own results.

If I had unlimited resources, I would create more long-term prospects for young scientists. We train so many exceptionally talented young people for years in academic studies and PhDs. It takes a lot of time and money and then there are hardly any prospects afterwards. As a result, we regularly lose the best people with outstanding technical skills, who should be given more time for further scientific development. Unfortunately, policymakers are doing exactly the opposite, effectively banning postdocs from working after four years. With more money, these highly qualified scientists could be given long-term or even permanent positions, thus keeping their talent in research. For example, in specialized core facilities and platforms, where complex technologies, equipment and expertise are reliably available to research networks beyond the boundaries of an institute.

I can think of many. Out of personal interest, I would probably choose Uri Scheft, the founder of the Lehamim bakery in Tel Aviv. As an amateur baker, I would love to know all the tricks of the trade for making the perfect rugelach, babka or challah. He might also be interested in German cream cakes... |

|

|

|

Boston, 1974: Unlike his MIT classmates, chemical engineer Robert Langer had no interest in working for the oil giants. He turned down more than 20 job offers because he wanted to make a difference in people’s lives. He was fascinated by biology and medicine. At the time, Judah Folkman, a surgeon at Harvard and Boston Children’s Hospital, was thinking about treating cancer in unconventional ways. Folkman sometimes hired unusual people, a colleague had advised him. So, Langer ended up working as a dark horse in the lab of another dark horse. Fifty years later, we know what a stroke of luck that was. Together, they achieved what their peers considered impossible. Folkman, a surgeon, wanted to cut off the supply of nutrients to tumors. It was a radically new approach to cancer treatment and one that few believed would work. To do this, he not only wanted to develop a drug to prevent blood vessels from growing toward the tumor. He also needed a way to package it so that the drug would be released gradually at a suitable site in the body. Langer, who has been experimenting with polymers, was tasked with devising the material in which to package the drug. After hundreds of failures, he succeeded. Today, the approach seems obvious. But at the time, Langer was somewhat of a pariah: Chemical engineers did not work on medical projects nor were they thought of as entrepreneurs – and he was the only chemical engineer at the hospital. Until biomedical engineering became an established field in the U.S., individual researchers faced pushback from all sides. Today, few universities can afford to ignore the field. They are surrounded by start-ups that turn ideas and prototypes into marketable products. The list of patents and biotechs initiated by Bob Langer alone is too long to mention. Moderna, a producer of mRNA vaccines against COVID, is the most recent success. Germany can point to world-class research in both biomedicine and engineering. But so far these fields are hardly linked here. Given our aging population, we cannot afford to continue in this way! To stay healthy as long as possible and keep our healthcare system affordable, we need a culture that fosters innovation, problem-solving, and entrepreneurship. Ultimately, it is not just about tailoring treatments more effectively to individual patients and making them scalable; we also need to detect diseases earlier or if possible, prevent them from developing in the first place. Achieving this requires new diagnostics, predictive models, implants, and drugs. The innovations of the past decade, from artificial intelligence and single-cell analysis to CRISPR and imaging, have laid the foundation. But that is not enough. For example, for gene therapy to help patients, CRISPR must be delivered to the right place in the body. You can’t do that without biomedical engineering! The same is true if we want to create cells, tissues and organs for transplantation. In the Helmholtz Association, we have all the prerequisites to leverage the potential of bioengineering and expedite the transformation of biology-inspired technologies into marketable products: The multidisciplinary expertise and technological infrastructure across six research fields create an environment that is unique in the world. We simply need to assemble the puzzle pieces thoughtfully and unite people who have never collaborated before. At the Max Delbrück Center, we are currently hosting Milica Radisic from the Institute of Biomedical Engineering at the University of Toronto for a three-year collaborative project. She is working on supplying blood vessels to organs-on-a-chip. She completed her Ph.D. under the mentorship of Bob Langer. Her mentor's advice was: “Work on important problems, surround yourself with the best people – and think BIG!” Picture: Peter Himsel/Max Delbrück Center

Briefing: Helmholtz Biomedical Engineering (PDF) |

|

|

|

|

The Moon is now available on Earth for training astronauts, developing technologies and preparing for long-term missions. The German Aerospace Center (DLR) and the European Space Agency (ESA) have jointly built the LUNA research facility, which has now been opened. Among other things, the LUNA hall contains a 700 square meter simulated lunar surface. It is filled with “lunar dust” that is deceptively similar to real regolith. Stones and rocks are modeled after lunar geology, and a sun simulator creates lunar lighting conditions. The Gravity Offloading System will soon replicate lunar gravity: Over the next few months, carriages and cable systems will be installed on the ceiling to allow astronauts or rovers to move as they would on the Moon, with one-sixth of their own weight. The LUNA facility will be available for national and international research institutions, space agencies, universities and student groups, industrial companies and start-ups to conduct experiments and test campaigns. |

Published by: Helmholtz Association of German Research Centres, Anna-Louisa-Karsch-Str.2, 10178 Berlin Questions to the editors should be sent to monthly@helmholtz.de

No subscription yet? Click here to register If you no longer wish to receive our newsletter, simply click here: Unsubscribe © Helmholtz

|

![[Translate to Englisch:] [Translate to Englisch:]](https://www.helmholtz.de/assets/helmholtz_gemeinschaft/_processed_/5/5/csm_Franziska_Roeder_Monthly_600x600_fb078b8a96.png)